Laminated Glass vs Toughened Glass: A Comprehensive Guide

Are you unsure whether to choose laminated or toughened glass for your next project? This guide is for homeowners, businesses, and anyone interested in learning about laminated and toughened glass. Whether you’re renovating your home, building a new office, or simply curious about different glass options, this information will be helpful.

Table of Contents

Quick Comparison - Key Takeaways

| Feature | Laminated Glass | Toughened Glass |

|---|---|---|

| Construction | Multiple glass layers with interlayer (e.g., PVB) | Single glass pane, heat-treated |

| Safety | Holds together when shattered | Breaks into small granules |

| Strength | Durable, but less strength than toughened glass | Very strong, resistant to physical force |

| Insulation | Excellent sound and UV insulation | Basic insulation properties |

| Applications | Car windshields, high-rise buildings | Shower doors, glass tables, oven windows |

| Alterations | Can be cut or drilled post-production | Must be cut to size before tempering |

What is Laminated Glass?

- Prevents shattering into sharp fragments, reducing injury risk.

- Ideal for car windshields, high-rise buildings, and other safety-critical applications.

- Dampens sound waves, improving acoustic comfort in buildings and vehicles.

- Maintains a single sheet of glass even when broken, preventing pieces from falling out.

- Resists wind, impact, and explosions better than standard glass.

- Deters break-ins and vandalism by making entry more difficult.

- Certain interlayers block harmful UV rays, protecting interiors from fading and sun damage.

- Colored or patterned interlayers can be used for aesthetic purposes.

- Can be combined with other glass types for enhanced properties like heat insulation or fire resistance.

What is Toughened Glass?

- Up to 5 times stronger than regular glass, resisting strong impacts and pressure.

- Ideal for applications like shower doors, glass doors and tables, and oven windows.

- Withstands high temperatures without cracking or warping, making it perfect for oven windows and cookware.

- Shatters into small, blunt granules instead of sharp shards, minimizing injury risk.

- Suitable for safety-critical applications like shower doors and high-traffic areas.

- Pre-stressed during production, maintaining its strength even after breaking.

- Resists scratches, chips, and wear and tear better than regular glass.

- Smooth, non-porous surface simplifies cleaning and maintenance.

- Can be combined with other glass types for additional features like insulation or tinting.

- Sleek, minimalist appearance complements contemporary design styles.

Making the Decision: Laminated vs Toughened Glass

Making the right choice between laminated and toughened glass can feel like navigating a maze of options. While both offer significant advantages over standard glass, their unique strengths and limitations make them suitable for different situations. To help you navigate this decision, let’s delve deeper into their key features, alongside some additional factors to consider:

Strength & Durability

- Toughened: Reigns supreme with 4-5x the strength of regular glass, ideal for high-impact areas like shower doors, tables, and oven windows.

- Laminated: While not as strong, its multi-layer construction offers impressive durability. Even when broken, shards stick to the interlayer, minimizing injury risk.

Safety

- Toughened: Shatters into small, blunt granules, reducing the risk of severe cuts compared to sharp shards.

- Laminated: Holds together when broken, preventing dangerous shards from falling and promoting safety in critical areas like car windshields, buildings, and balustrades.

Insulation

- Laminated: Shines in both energy efficiency and sound insulation thanks to the interlayer. Blocks UV rays and can be customized for enhanced insulation.

- Toughened: Offers basic thermal insulation, but not as effective as laminated glass.

Additional Factors to Consider

- Cost: Toughened glass is generally more affordable due to its simpler production process.

- Appearance: Laminated glass offers customization with colored or patterned interlayers, while toughened glass has a clean, minimalist look.

- Maintenance: Both are easy to clean, but laminated glass may require slightly more care for the interlayer.

- Shape and Size: Toughened glass has limitations due to tempering, while laminated glass is more versatile.

- Heat Treatment: Toughened glass cannot be further treated with heat, limiting its use. Laminated glass allows for additional treatments.

- Special Features: Certain laminated types offer UV protection, blast resistance, or fire resistance. Toughened glass can be combined with films for added functionality.

- Availability: Toughened glass is widely available, while laminated options may be limited based on thickness, interlayer type, and customization.

- Choose Toughened for maximum strength and impact resistance.

- Choose Laminated for superior safety, security, and insulation.

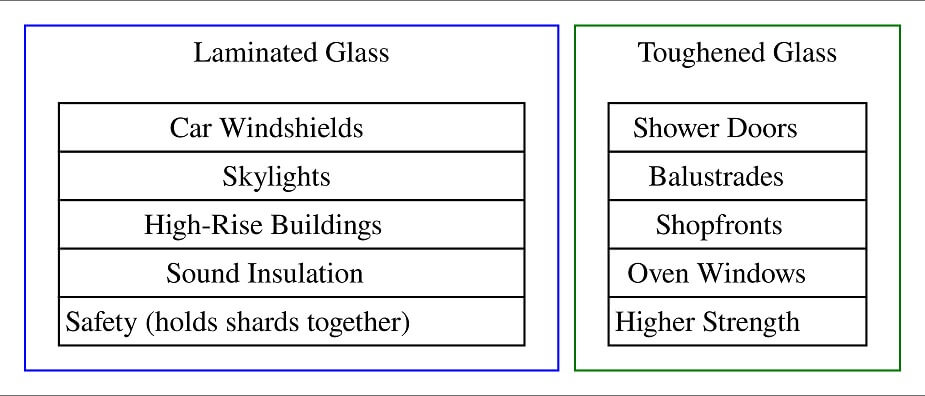

Applications of Laminated and Toughened Glass

- Safety-critical areas (windshields, buildings, skylights), security, and insulation.

- High-strength applications (shower doors, tables, balustrades, shopfronts).

Choosing Between Laminated Glass & Toughened Glass

Ultimately, choosing between laminated and toughened glass depends on your specific needs and priorities. Consider the following factors:

- Safety Requirements: If safety is paramount, laminated glass is preferable due to its ability to hold together when broken.

- Sound and UV Insulation: Laminated glass excels in sound and UV insulation, making it ideal for noise-sensitive environments or areas exposed to strong sunlight.

- Strength and Durability: If the glass will be subject to heavy physical impacts, toughened glass is a better choice due to its superior strength.

- Post-Production Alterations: Laminated glass allows for cutting or drilling after production, while toughened glass requires these alterations before tempering.

- Budget: Toughened glass generally costs less than laminated glass due to its simpler production process.

By carefully evaluating your needs and considering these factors, you can make an informed decision and choose the type of glass that best suits your project.

Khalil is the owner of Splendid Window Glass Repairs and has over 8 years experience as a glazier specialising in window glass repair, replacement and installations. Khalil takes great pride in his work and prides himself on providing an excellent service to all of his customers, no matter how big or small the job may be.

Copyright © 2024 Splendid Window Glass Repairs

SEO & Website by Wong Way SEO